Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Our Steel Coils are supplied and exported by us all over USA, Australia, Canada, and Gulf Countries especially in Dubai, Bahrain, Iran, Iraq, Kuwait, Oman, Qatar, Saudi Arabia, and the United Arab Emirates etc.

Contact us today to request a free estimate or send an enquiry on : marketing@mellowsteel.com

Whatsapp: +86 13827707434

Mellow Stainless Steel specializes in the distribution and export of stainless steel coils in various grades, including 304, 316, 201, and 430. We offer a comprehensive range of finishes, including BA, 2B, and galvanized cold-rolled stainless steel coils.

Our stainless steel coils are available in the desired forms to meet client specifications, ensuring flexibility and customization for various applications.

Stainless steel coils are essential products in the steel industry, characterized by their rolled configuration. We provide wide coils, typically manufactured at a width of 1250mm, commonly referred to as mill edge coils, The thickness can vary from 0.02mm to 6mm.

For competitive pricing and high-quality products, compare our offerings and discover the advantages of working with Mellow Steel.

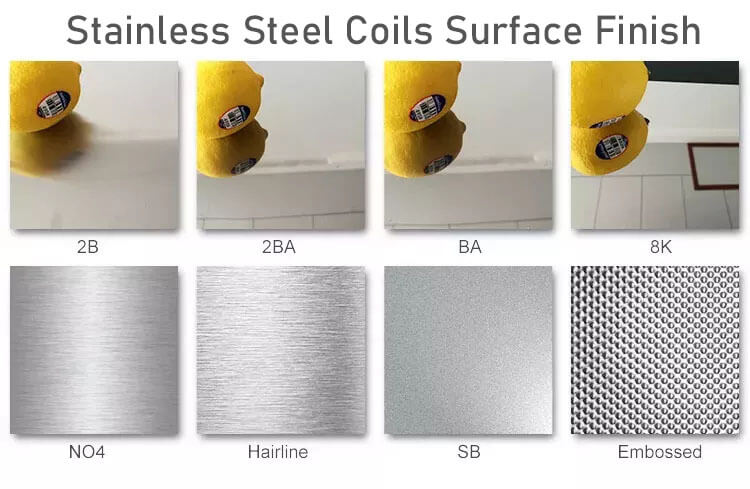

Surface finish of coils available: NO.1, 2B, 2H(Rerolled Bright), BA, No.4, 8K (Mirror), HL (Hairline), Polishing Bright, etc.

1. Standard export sea packaging: Waterproof Paper Winding+PVC Film+Strap Banding+Wooden Pallet or Wooden Case;

2. Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

3. Other special packaging will be designed as customer’s request;Eye to wall and eye to sky are both available;

4. By International Express: DHL/UPS/FEDEX/EMS and our own express line;

5. By air or By sea;

6. Shipping port: Shenzhen, Foshan, Guangzhou or as your request.

Stainless steel coils are the most widely used type of metal coil in the market. They are mainly used for making pipes, tubes and sheets. These stainless steel coils are manufactured using different types of raw materials and advanced technology.

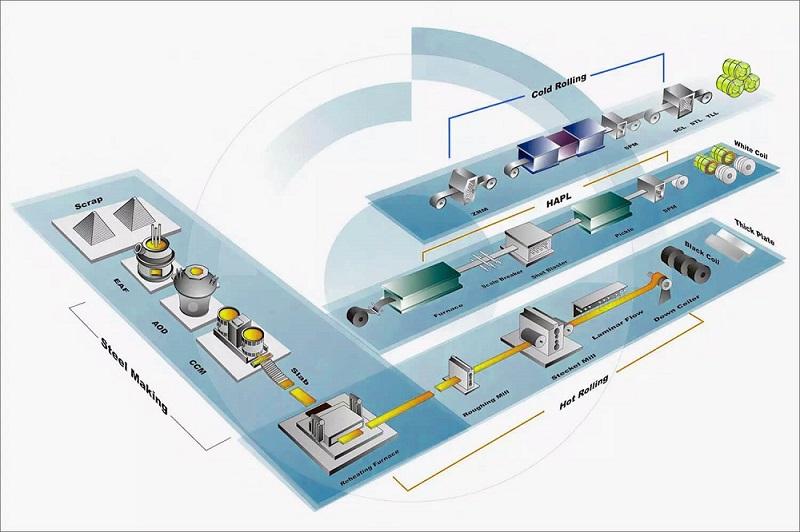

Stainless steel coils are made using several processes like hot rolling, cold rolling and extrusion. The process of making these coils depends on their thickness, diameter, length and width.

Most common process used to manufacture stainless steel coils is hot rolling process. It involves melting the raw material at high temperature and then shaping it into desired forms by rolling them through a series of rollers that have varying degrees of hardness. This process results in producing large sized products with a uniform thickness, size and shape.

The second commonly used process is cold rolling process which is carried out under controlled conditions so as to maintain product quality during production stages. In this process, the material undergoes three processes namely roughing pass (first pass), semi-finishing pass (second pass) and finishing pass (third pass). This method produces products with high dimensional accuracy and good surface finish with low yield loss due to less friction during rolling process.

Mill edge is a non-trimmed edge appearance after hot or cold rolling and annealing/pickling process. It usually leaved an irregular pinhole line on the edge side around 10mm to 15mm.

Slit/slitting edge means we will trim irregular pinhole line on our slitting machine.

| Austenitic Stainless Steel | 201, 301, 303, 304, 304L, 309S, 310S, 316/316L, 321, 347, 904L, etc |

| Martensitic Stainless Steel | 410, 414, 416, 416, 420, 431, 440A, 440B, 440C, etc |

| Duplex Stainless Steel | S31803, S32101, S32205, S32304, S32750, etc |

| Ferritic Stainless Steel | 429, 430, 433, 434, 435, 436, 439, etc |

stainless steel with an austenitic structure at room temperature. Steel contains Cr≈18%, Ni≈8%-25% and C≈0.1%. Steel has high toughness and plasticity, but low strength.

A steel whose mechanical properties can be adjusted by heat treatment. It has different strength and toughness at different tempering temperatures.

Austenitic and ferrite each account for about half of the structure. When the C content is low, the Cr content is 18% to 28%, and the Ni content is 3% to 10%. Some steels also contain alloying elements such as Mo, Cu, Si, Nb, Ti, and N. This type of steel has the characteristics of austenitic and ferritic stainless steel

It contains 15% to 30% chromium and has a body-centered cubic crystal structure. This type of steel generally does not contain nickel, and sometimes contains a small amount of Mo, Ti, Nb and other elements. This type of steel has the characteristics of large thermal conductivity, small expansion coefficient, good oxidation resistance, and excellent stress corrosion resistance.

Stainless steel coils find applications in a wide range of industries due to their versatile properties. Some of the most common applications include: Hinges: Stainless steel coils are used to manufacture hinges due to their corrosion resistance and strength.

● Cookware: Stainless steel is a popular material for cookware, as it is hygienic, easy to clean, and resistant to staining or flavor transfer.

● Cutlery: Knives and other cutlery items are often made from stainless steel due to their corrosion resistance and durability.

● Household hardware: Stainless steel coils are used to produce various household hardware items, such as door handles, drawer pulls, and bathroom fixtures.

● Surgical instruments: Stainless steel’s corrosion resistance and biocompatibility make it suitable for use in surgical instruments.

● Major appliances: Many major appliances, including refrigerators, dishwashers, and ovens, use stainless steel for their exteriors and components.

● Industrial equipment: Stainless steel coils are used in industries such as sugar refineries for their corrosion resistance in harsh environments.

● Automotive and aerospace structural alloy: Stainless steel is used in the manufacture of structural components in the automotive and aerospace industries due to its strength and corrosion resistance.

● Construction material: Stainless steel coils can be used as construction material in large buildings, providing strength and durability.

The wide range of applications demonstrates the versatility and reliability of stainless steel coils across different industries.

Copyright © 2004-2022 Foshan Mellow Stainless Steel Co., Ltd. | All Rights Reserved 粤ICP备19129739号 Sitemap Kinlife Group Kinlife Boat Kindlemetal Stainless Steel Kitchen