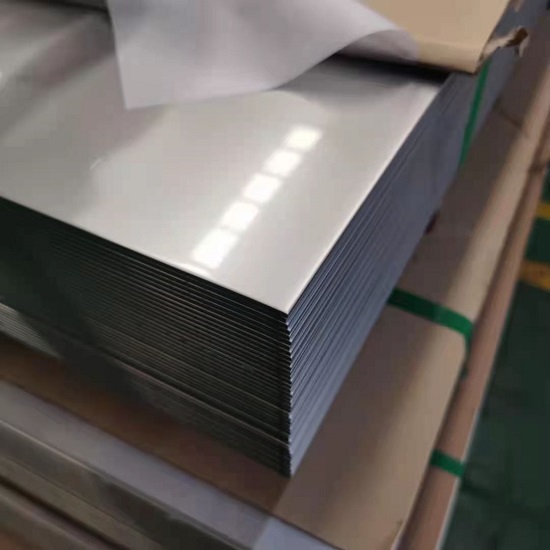

Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Our Stainless Steel are supplied and exported by us all over USA, Australia, Canada, and Gulf Countries especially in Dubai, Bahrain, Iran, Iraq, Kuwait, Oman, Qatar, Saudi Arabia, and the United Arab Emirates etc.

Contact us today to request a free estimate or send an enquiry on : marketing@mellowsteel.com

Whatsapp: +86 13827707434

Austenitic stainless steels are the most widely used type of stainless steel, valued for their excellent corrosion resistance, ductility, and versatility.

These steels contain high levels of chromium (typically 16-26%) and nickel (6-22%), which contribute to their resistance to rust and staining.

The face-centered cubic (FCC) crystal structure gives them high toughness, even at low temperatures.

This type of stainless steel is non-magnetic in its annealed state, a useful property for certain applications. Among the common grades, 316L, 321, and 310S each offer unique benefits:

• 316L: With added molybdenum, 316L is highly resistant to pitting and crevice corrosion, making it ideal for harsh environments such as marine and chemical processing.

• 321: Stabilized with titanium, 321 offers excellent resistance to intergranular corrosion after welding, making it suitable for high-temperature applications.

• 310S: Designed for extreme heat, 310S can withstand temperatures up to 1035°C, making it a choice material for high-temperature industrial furnaces and petrochemical applications.

This tailored composition and structure make austenitic stainless steels suitable for a wide range of demanding applications, from food processing to medical devices and beyond.

Mellow inventory includes 316/316L (UNS S31600 / S31603), in sheet, sheet coil, plate, plate coil, bar, structural and tubular products.Generally, this grade is dual-certified to meet both 316 and 316L. Alloy 316/316L is ideally suited for applications requiring corrosion resistance superior to Type 304 and has good elevated temperature strength.

Corrosion Resistance:

● Generally more resistant than 304 in range of atmospheric environments and many corrosive media due to the increased chromium and molybdenum content.

● Subject to pitting and crevice corrosion in warm chloride environments, and to stress corrosion cracking above about 122°F (50°C).

● Considered resistant to potable water with up to about 1000mg/L chlorides at ambient temperatures, reducing to about 500mg/L at 140°F (60°C).

● Usually regarded as the “marine grade stainless steel” – but is not resistant to warm sea water.

Heat Resistance:

● Good oxidation resistance in intermittent service to 1600°F (870°C) and in continuous service to 1700°F (925°C)

● Grade 316L is more resistant to carbide precipitation.

Applications:

● Food preparation equipment, especially in chloride environments

● Chemical processing, equipment

● Laboratory benches and equipment

● Rubber, plastics, pulp & paper machinery

● Pollution control equipment

● Boat fittings, value and pump trim

● Heat exchangers

● Pharmaceutical and textile industries

● Condensers, evaporators and tanks

Mellow inventory now includes Alloy 321 (UNS S32100) in sheet, sheet coil, plate, round bar, processed flat bar and tubular products.

Corrosion Resistance:

● exhibits good general corrosion resistance that is comparable to 304.

● developed for use in the chromium carbide precipitation range of 1800 – 1500°F (427 – 816°C) .

● can be used in most diluted organic acids at moderate temperatures .

● can be used in pure phosphoric acid at lower temperatures.

● can be used in up to 10% diluted solutions at elevated temperatures.

● resists polythionic acid stress corrosion cracking in hydrocarbon service.

● utilized in chloride or fluoride free caustic solutions at moderate temperatures.

● does not perform well in chloride solutions, even in small concentrations, or in sulfuric acid service.

Applications:

● Aerospace – piston engine manifolds

● Chemical Processing

● Expansion Joints

● Food Processing – equipment and storage

● Petroleum Refining – polythionic acid service

● Waste Treatment – thermal oxidizers

Mellow inventory now includes 310/ 310S Plate and Processed Flat Bar (Alloy 310 UNS S31000 / Alloy 310S UNS S31008), ideally suited for high-temperature applications such as heat treatment and chemical processing equipment.

Corrosion Resistance:

● Provides excellent corrosion resistance

● High chromium content allows for good aqueous corrosion resistance

● Excellent resistance at normal temperatures and also has good resistance to oxidizing and carburizing atmospheres

Heat Resistance:

● Good resistance to oxidation in intermittent service in air at temperatures up to 1040°C and 1150°C in continuous service.

● Good resistance to thermal fatigue and cyclic heating.

● Widely used where sulphur dioxide gas is encountered at elevated temperatures.

● Continuous use in 425-860°C range not recommended due to carbide precipitation, if subsequent aqueous corrosion resistance is needed.

● Generally used at temperatures starting from about 800 or 900°C – above the temperatures at which 304H and 321 are effective.

Applications:

● Furnace Parts

● Oil Burner Parts

● Heat Exchangers

● Welding Filler Wire and Electrodes

● Annealing Covers

● Combustion Tubes

● Fire Box Sheets

Copyright © 2004-2022 Foshan Mellow Stainless Steel Co., Ltd. | All Rights Reserved 粤ICP备19129739号 Sitemap Kinlife Group Kinlife Boat Kindlemetal Stainless Steel Kitchen