Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Email: marketing_jane@mellowsteel.com

Tel/Whatsapp: +86 13138226177

Product information

|

Product Name |

|

|

Technical Standard |

JIS,AISI, ASTM,GB,DIN,EN |

|

Steel Grade |

201/201L/304/304L/316/316L321/309S/310S/904L |

|

Type |

Stainless steel sheet/ plate/coil |

|

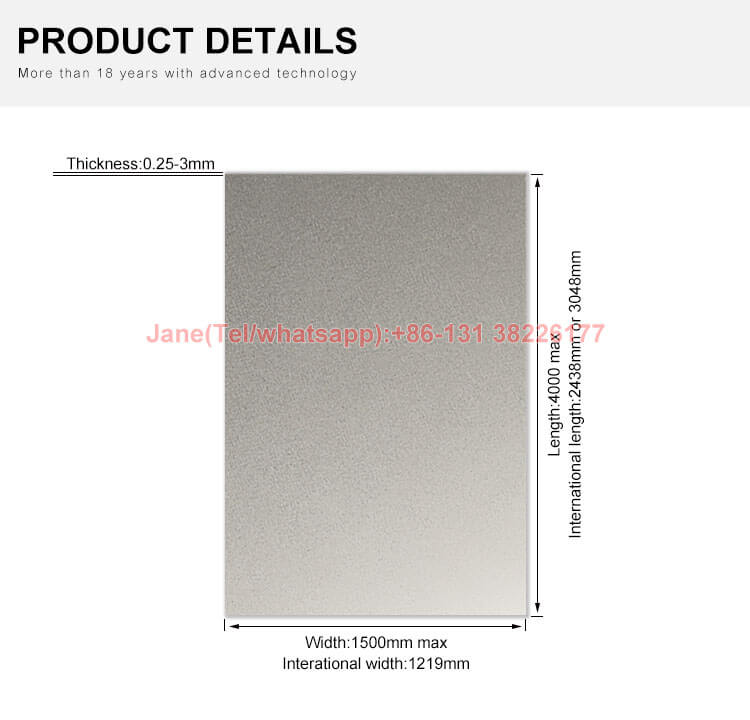

Thickness |

Cold rolled:0.1~3.0mm or customer's requirement |

|

Hot rolled:3mm~100mm or customer's requiremen |

|

|

Width |

600~2500mm according to customer's requirement |

|

Length |

1000mm~8000mm or customer's requirement |

|

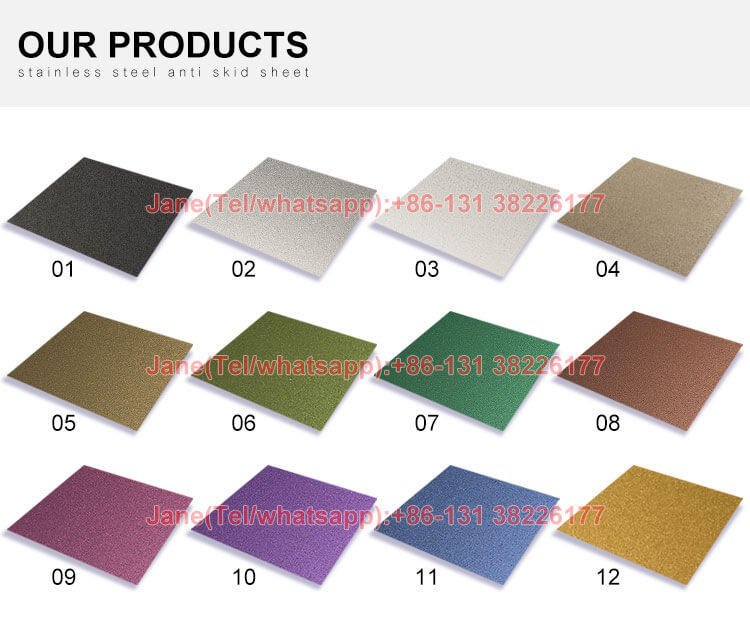

Surface |

NO.1 NO.4 2D 2B HL BA 6K 8K Mirror etc. |

|

Quality |

Approved by SGS,ISO |

|

Package |

Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by seven steel belt.or according to customer's requirement |

|

Export market |

Europe, Africa, Central Asia, Southeast Asia, Middle East, South America, North America, etc |

|

Trade term |

FOB CIF CFR |

|

Loading port |

Tianjin Shanghai Qingdao,etc. |

|

|

Chemical Composition (%) |

Mechanical Performance |

|||||||

|

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Hardness |

|

201 |

≤0.15 |

≤1.00 |

5.5/7.5 |

≤0.060 |

≤0.030 |

3.5/5.5 |

16.0/18.0 |

- |

HB≤241,HRB≤100, HV≤240 |

|

304 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

8.0/11.0 |

18.00/20.00 |

- |

HB≤187,HRB≤90,HV≤200 |

|

316 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

10.00/14.00 |

16.0/18.0 |

2.00/3.00 |

HB≤187, HRB≤90 HV≤200 |

|

316L |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

10.00/14.00 |

16.0/18.0 |

2.00/3.00 |

HB≤187, HRB≤90 HV≤200 |

|

410 |

≤0.15 |

≤1.00 |

≤1.25 |

≤0.060 |

≤0.030 |

≤0.060 |

11.5/13.5 |

- |

HB≤183, HRB≤88 HV≤200 |

|

430 |

≤0.12 |

≤1.00 |

≤1.25 |

≤0.040 |

≤0.03 |

- |

16.00/18.00 |

- |

HB≤183, HRB≤88 HV≤200 |

FAQS

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials. .

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-45 days, and may be delayed if the demand isextremely large or special circumstances occur.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It caneffectively protect products from corrosion during ocean transportation.

Copyright © 2004-2022 Foshan Mellow Stainless Steel Co., Ltd. | All Rights Reserved 粤ICP备19129739号 Sitemap Kinlife Group Kinlife Boat Kindlemetal Stainless Steel Kitchen