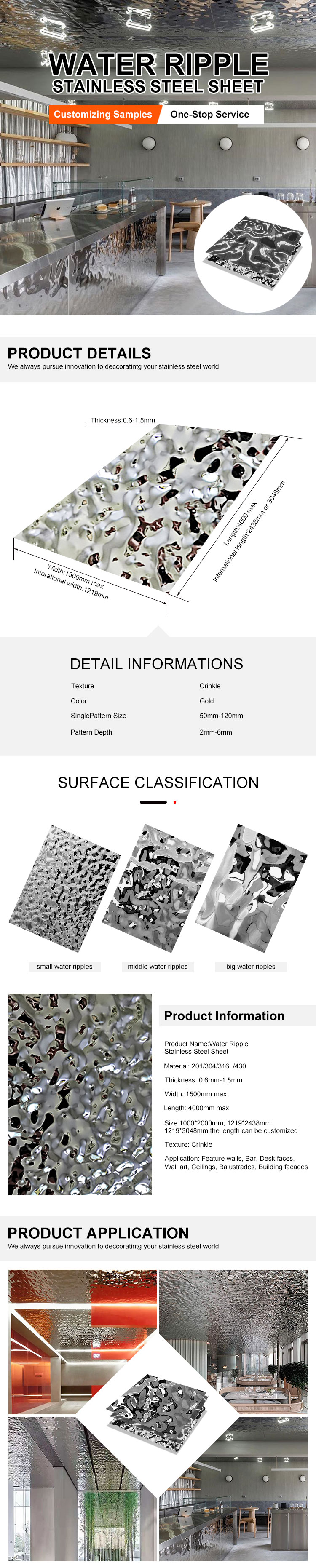

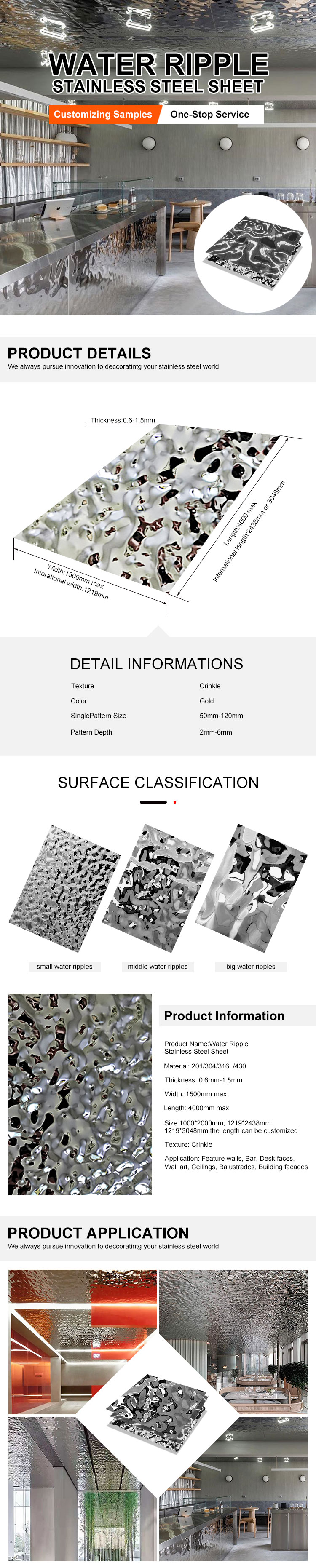

Product information

316 water ripple color stainless steel is a high-end decorative material made of 316 stainless steel as the base material and processed by special process. 316 stainless steel because of its molybdenum element, excellent in corrosion resistance, oxidation resistance and strength, very suitable for use in wet, acid and alkali environments. The addition of water ripple pattern not only gives the product a unique visual effect, but also enhances the anti-scratch performance of the surface, making it shine in the field of decoration.

Color processing technology through the vacuum ion coating (PVD) process, stainless steel surface treatment into gold, rose gold, black titanium, violet and other colors. These colors are not only bright and durable, but also have a strong resistance to fading, providing designers with more creative options.

Application scenario

- Interior decoration: background wall, ceiling, elevator decoration board, etc.;

- Building exterior wall: curtain wall, column decoration;

- Furniture manufacturing: cabinet door panel, table decoration;

- Commercial Spaces: decorative panels for hotels, restaurants and shopping malls.

Product specification introduction

- Material: 316/316L stainless steel

- Thickness: 0.5mm-3.0mm (customizable)

- Size: The conventional size is 1220mm × 2440mm, supporting customized large-size plates

- Surface treatment: water ripple pattern + PVD color coating

- Color selection: Gold, rose gold, black titanium, bronze, Champagne gold, etc

- Corrosion resistance: suitable for high salt, high humidity environment

- Machining performance: can be cut, bending, welding and other secondary processing

If there are special needs, we can customize production according to the design drawings provided by customers.

Stainless steel water ripple production process

1. Select the substrate

The selection of high-quality 316 stainless steel substrate ensures excellent corrosion resistance and strength.

2. Surface treatment

The stainless steel sheet is polished or brushed to ensure that the surface is smooth and smooth, laying the foundation for subsequent processing.

3. Water ripple embossing

Professional equipment is used to press clear and uniform patterns of water ripples on the stainless steel surface through the mold. This process requires precise control of pressure and temperature to ensure the consistency of the grain.

4. PVD vacuum coating

In a vacuum environment, through the physical vapor deposition process (PVD), titanium ions or other metal ions are deposited on the surface of stainless steel, thus forming a colorful layer of color.

5. Quality inspection and packaging

Each piece of finished product is subjected to rigorous quality testing, including color uniformity, pattern integrity and corrosion resistance tests. After qualified, the protective film cover and safety packaging are carried out.

The purchase process from China to foreign countries

If you are an overseas customer and want to purchase 316 Water Ripple color stainless steel products, the following is the standard purchase process:

1. Needs communication

Contact suppliers via email or online communication tools to clarify your needs, including product specifications, colors, quantities and delivery times.

2. Quotation and sample confirmation

The supplier will provide a detailed quotation according to your requirements and can send samples for you to confirm the quality.

3. Sign a contract

Both parties confirm the details of the order and sign a formal contract, and pay an advance payment (usually 30%-50%).

4. Production and quality inspection

The factory produces according to the requirements of the order, and carries out strict quality inspection after completion to ensure that the product meets the standard.

5. Export declaration and transportation

The supplier is responsible for handling export customs formalities and arranging sea, air or express transportation according to customer needs.

6. Customs clearance and receipt

Customer completes local customs clearance upon receipt of the goods and pays the balance (if applicable).

7. After-sales service

If you encounter problems during use, you can contact the supplier for technical support or after-sales service at any time.

FAQS

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials. .

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-45 days, and may be delayed if the demand isextremely large or special circumstances occur.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It caneffectively protect products from corrosion during ocean transportation.