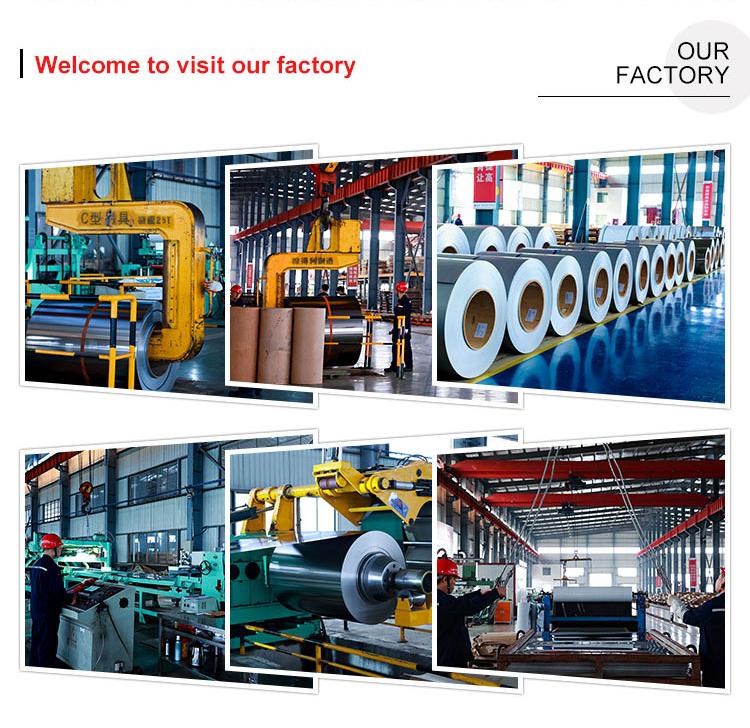

Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Email: marketing@mellowsteel.com

Tel/Whatsapp: +86 13827707434

Product information

|

Brand |

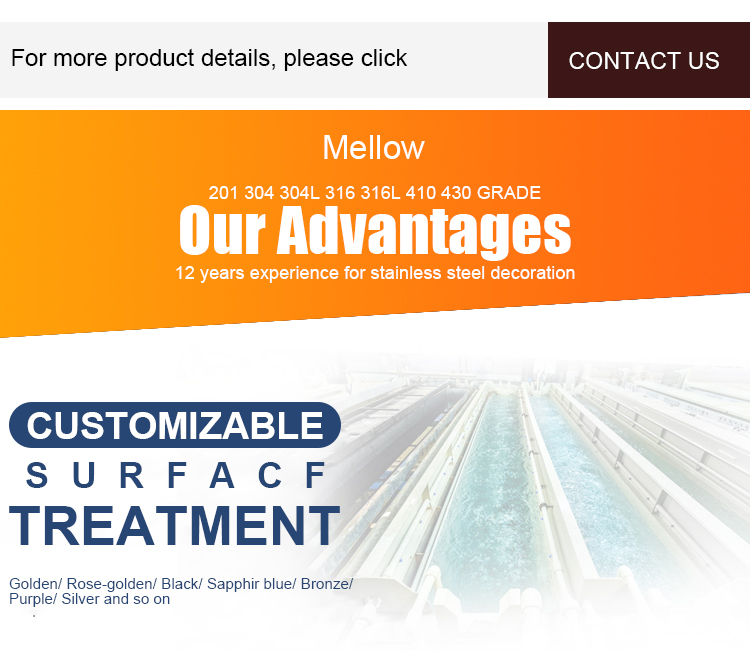

Mellow |

|

Commodity |

Austenitic, Ferritic, Martensitic, Duplex, Cold rolled, Hot rolled |

|

Grade |

201, 202, 301, 304, 304j1, 304l, 321, 309s, 310s, 2205, 409l, 410, 410s, 420, 420j1, 420j2, 430, 439, 409l, 443, 444, etc |

|

Standard |

ISO, JIS, ASTM, AS, EN, GB |

|

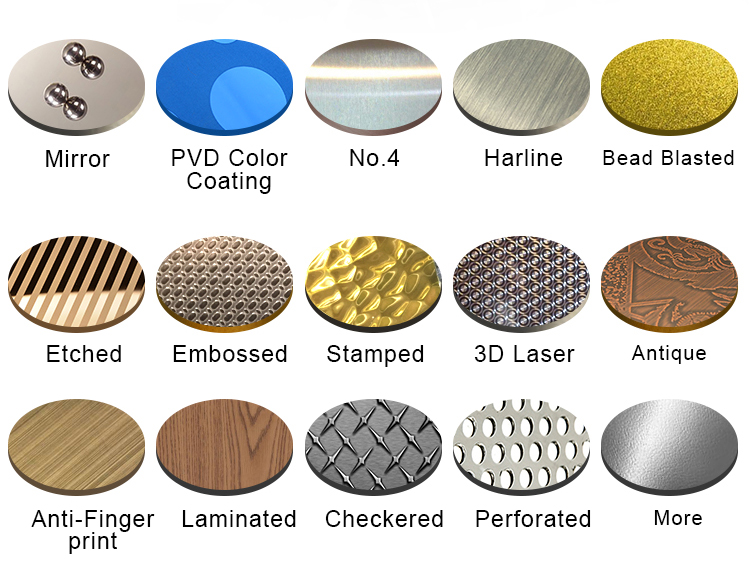

Surface |

N0.1, N0.2, N0.3, N0.4, N0.5, N0.6, N0.7, N0.8, 2D, 2B, HL, BA, 6K, 8K, etc |

|

Thickness |

0.1-200mm |

|

Width |

10-2000mm |

|

MOQ |

1MT |

|

Packaging |

Export standard, seaworthy |

|

Trade Term |

FOB, CFR, CIF |

|

Transport Type |

Container, bulk and train |

|

Payment terms |

T/T, L/C at sight,West Union,D/P,D/A,Paypal |

|

Delivery time |

15-35 days after confirmed order |

FAQS

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-45 days, and may be delayed if the demand isextremely large or special circumstances occur.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It caneffectively protect products from corrosion during ocean transportation.

Copyright © 2004-2022 Foshan Mellow Stainless Steel Co., Ltd. | All Rights Reserved 粤ICP备19129739号 Sitemap Kinlife Group Kinlife Boat Kindlemetal Stainless Steel Kitchen