Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Email: marketing@mellowsteel.com

Tel/Whatsapp: +86 13827707434

|

Product name |

Stainless steel sheet |

|

Grade |

201, 304, 316, 410, 430 |

|

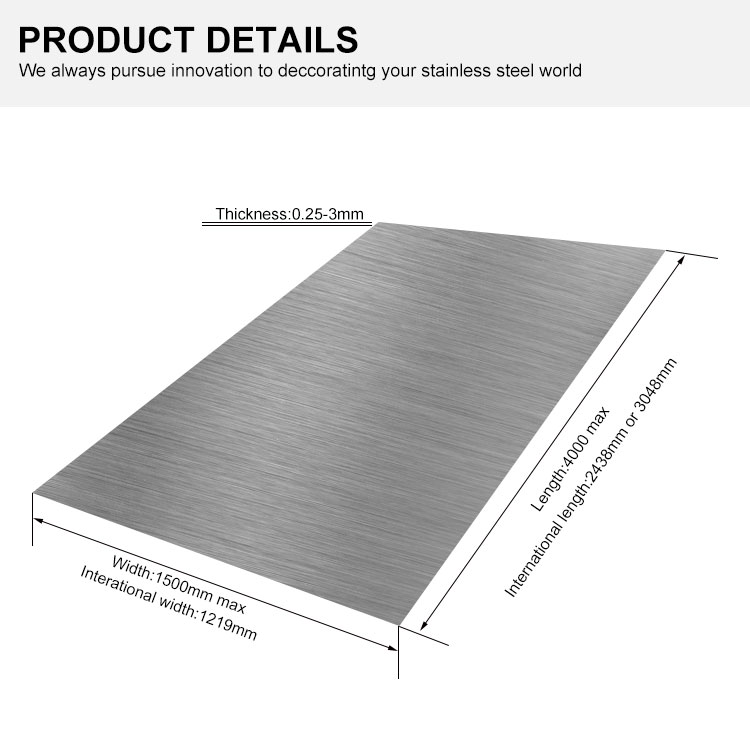

Thickness range |

0.3mm-3.0mm |

|

Width range |

600mm-1500mm |

|

Length |

2000mm, 2438mm, 3048mm,or customized |

|

Size |

1000mm*2000mm, 1219mm*2438mm, 1219mm*3048mm, or customized |

|

Finish |

2B, BA, No. 4, Hairline, 8K, embossed, etched, vibration, PVD color coated, sand blasted, Anti-fingerprint |

|

Color |

Gold, Black, Sapphire blue, Brown, Bronze, Purple, Champagne gold, Diamond, Rose gold, Rose red, etc. |

|

Lead time |

10 to 30 working days after the receipt of 30% deposit |

|

Packing |

Wooden pallet or according to customer's request |

|

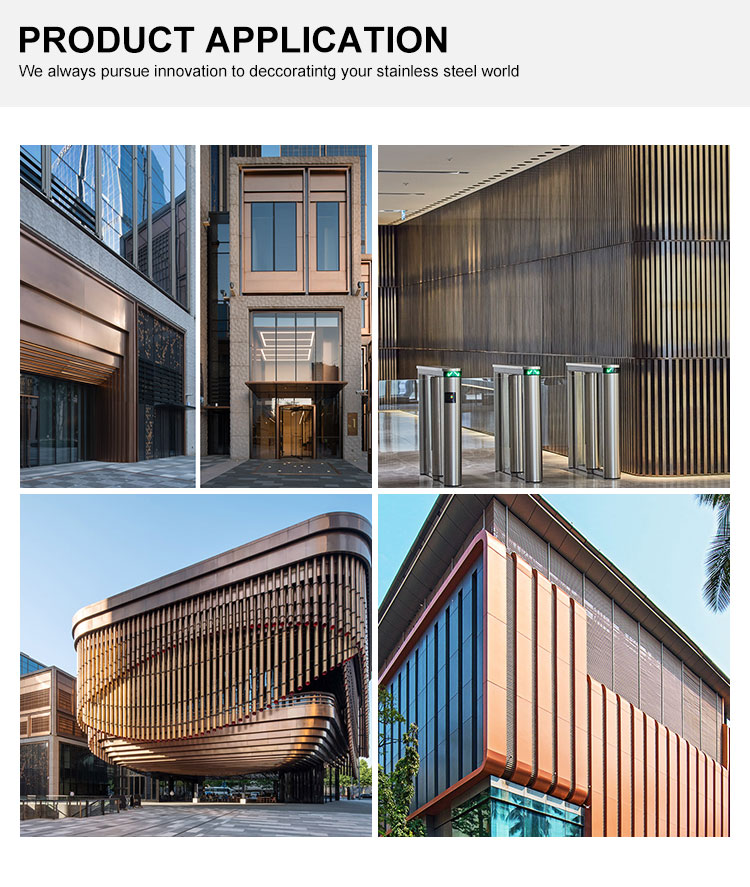

Application |

Interior/exterior/architectural/bathroom decoration, elevator decoration, hotel decoration, kitchen equipment, ceiling, cabinet, kitchen sink, advertising nameplate |

1.PVD (colored finish) – Simply called Physical vapor deposition (PVD) – identifies a number of vacuum deposition processes which is able to be used to create a thin coatings.

2.PVD is described as a process to produce a metal vapor that can be deposited on electrically conductive materials as a thin highly adhered pure metal or alloy coating.1.PVD (Physical Vapor Deposition) coating is a method of producing thin films through the condensation of a vaporized form of the desired coating material.

When applied to stainless steel plates, PVD coating enhances their performance in several ways.

It improves the corrosion resistance of the stainless steel, making it more durable and suitable for use in harsh environments.

The coating enhances the hardness and wear resistance of the steel, prolonging its lifespan and reducing maintenance requirements.

PVD coating also provides aesthetic benefits, offering a range of colors and finishes to suit different design requirements.

2.PVD coated stainless steel plates exhibit improved performance in terms of corrosion resistance, hardness, wear resistance, and aesthetics, making them a versatile and reliable choice for various applications.5. The benefits of colorful stainless steel sheets make them a versatile and durable material for various applications.

FAQS

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials. .

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-45 days, and may be delayed if the demand isextremely large or special circumstances occur.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It caneffectively protect products from corrosion during ocean transportation.

Copyright © 2004-2022 Foshan Mellow Stainless Steel Co., Ltd. | All Rights Reserved 粤ICP备19129739号 Sitemap Kinlife Group Kinlife Boat Kindlemetal Stainless Steel Kitchen