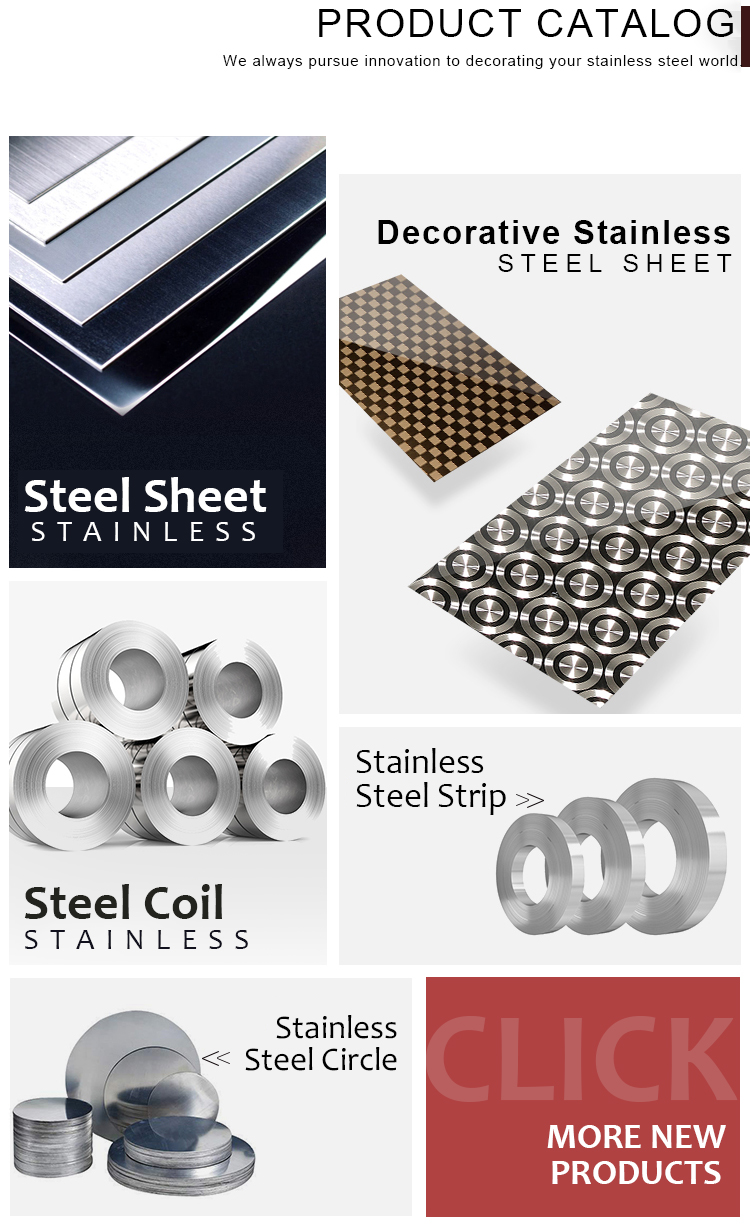

Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Email: marketing_jane@mellowsteel.com

Tel/Whatsapp: +86 13138226177

|

Product |

|

|

Standard |

ASTM,AISI,SUS,JIS,EN,DIN,BS,GB |

|

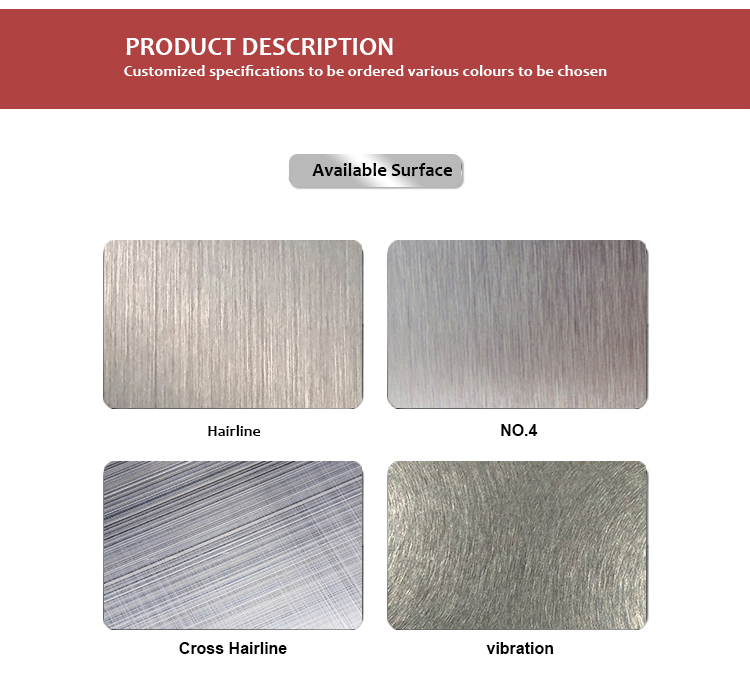

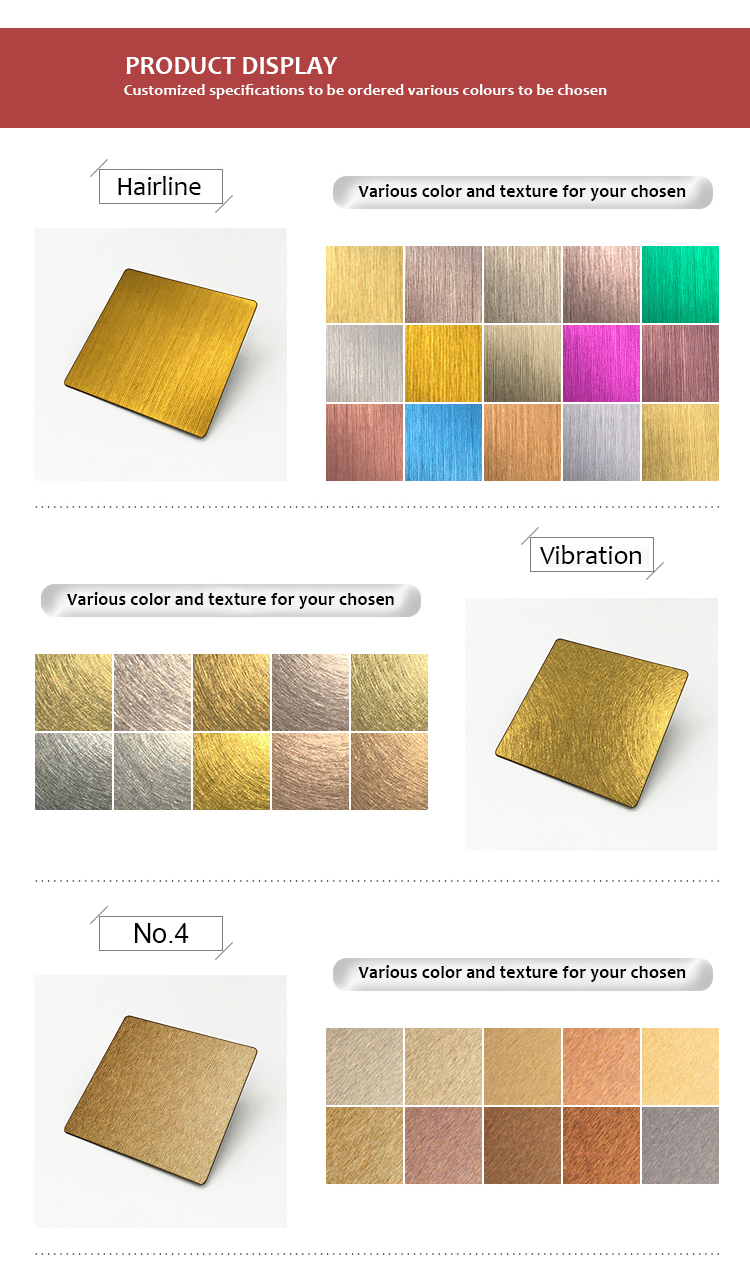

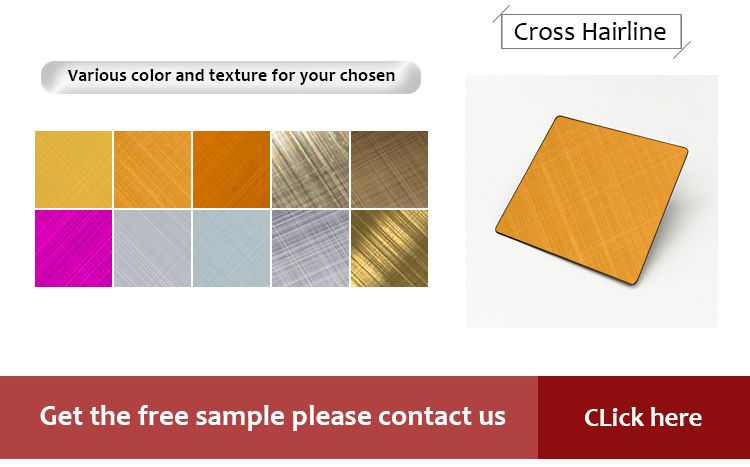

Finish(Surface) |

BA, 2B, 4K, 6K, 8K, NO.4, HL, Embossed, Perforated, Pickling white, Polished outside, Polished inside and outside |

|

Technique |

Hot Rolled / Cold Rolled |

|

Grade |

1020/1050/1060/1100/2011/2014/2017/2024/2A12/3003/3009/3A21/3A1 2/4004/4032/4047/5052/5083/5182/6061/6063/6082/7050/7A04 |

|

Standard Thickness |

1000mm/1250mm/1500mm, can be customized |

|

Standard Width |

1000mm/1250mm/1500mm, can be customized |

|

Additional Services |

Welding/Punching/Cutting/Bending/Decoiling |

|

Package Details |

Standard seaworthy package(protected by waterproof paper,wrapped in iron sheet, fixed by steel bars) |

Introduction of 316 stainless steel plate

Basic information

Material characteristics: 316 stainless steel plate belongs to austenitic stainless steel, with good corrosion resistance, heat resistance, low temperature strength and mechanical properties, non-magnetic, and excellent work hardening.

Corresponding grades: domestic standard grade is 0Cr17Ni12Mo2, American standard is SUS316, German/European standard is 1.4408.

Chemical composition

Main components: carbon (C) ≤0.08%, silicon (Si) ≤1.00%, manganese (Mn) ≤2.00%, phosphorus (P) ≤0.035%, sulfur (S) ≤0.03%, chromium (Cr) 16.00%-18.50%, nickel (Ni) 10.00%-14.00%, molybdenum (Mo) 2.00%-3.00%.

Element effect: Chromium can form a dense oxide film on the surface of stainless steel to improve corrosion resistance; nickel can enhance the toughness and corrosion resistance of stainless steel, so that stainless steel can maintain good performance even in low temperature environment; the addition of molybdenum further improves the corrosion resistance of stainless steel under harshconditions, especially the resistance to chloride pitting and crevice corrosion.

Physical properties

Density: about 7.98g/cm³.

Melting point: between 1398-1420℃.

Specific heat capacity: 0.502J/(g・℃) at 20℃.

Thermal conductivity: 12.1W/(m・℃) at 20℃, and the thermal conductivity will increase with the increase of temperature.

Linear expansion coefficient: 16.0×10-6/℃ at 20℃-100℃, and the linear expansion coefficient will gradually increase with the increase of temperature.

Resistivity: about 0.73Ω・mm²/m.

Longitudinal elasticmodulus: about 193kN/mm² at room temperature.

Mechanical properties

Specified non-proportional extension strength Rp0.2: not less than 310MPa.

Tensile strength Rm: not less than 620MPa.

Elongation after fracture A: not less than 30%.

Shrinkage surface after fracture Zc: not less than 40%.

Hardness: Brinell hardness HBW not more than 217, Rockwell hardness HRB not more than 95, Vickers hardness HV not more than 220.

Processing technology

Melting: Put high-quality chromium iron, nickel iron, molybdenum iron and other alloy raw materials and waste stainless steel into an arc furnace or induction furnace in a certain proportion for melting. By controlling the temperature, atmosphere and melting time in the furnace, various elements are fully fused to form a uniform steel liquid.

Refining: Use refining processes such as argon oxygen decarburization (AOD) and vacuum oxygen decarburization (VOD) to further reduce the carbon content in the molten steel, remove harmful impurities, adjust the content of alloying elements, and improve the purity and quality of the molten steel.

Casting: The refined molten steel is cast into a pre-designed mold, and after cooling and solidification, it forms a stainless steel slab. Common casting methods include continuous casting and die casting. Continuous casting has the advantages of high production efficiency and low cost, while die casting is suitable for producing slabs with some special specifications and high quality requirements.

Rolling: It includes two stages: hot rolling and cold rolling. Hot rolling is to heat the slab to a high temperature and then roll it through a rolling mill to gradually reduce its thickness and increase its width and length; cold rolling is to further roll the hot-rolled steel plate at room temperature to obtain higher dimensional accuracy, surface quality and mechanical properties.

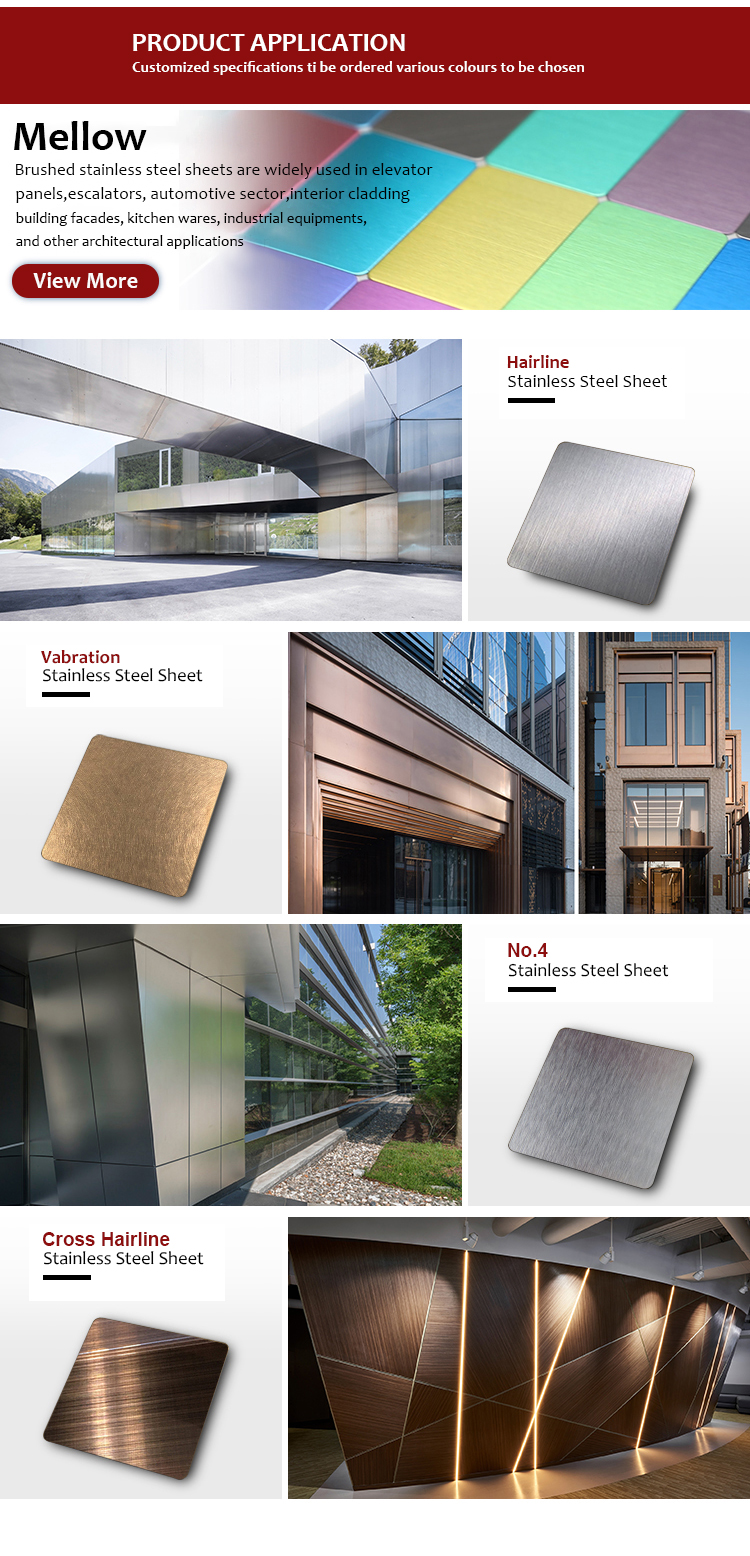

Surface treatment: In order to meet different usage requirements, 316 stainless steel plates also need various surface treatments, such as polishing, frosting, wire drawing, titanium plating, etc., to improve their aesthetics, corrosion resistance and wear resistance.

Corrosion resistance

Acid and alkali resistance: 316 stainless steel plate has good corrosion resistance in most organic acids, inorganic acids and alkaline solutions. For example, in acidic environments such as sulfuric acid, hydrochloric acid, and nitric acid, its corrosion resistance is significantly better than that of ordinary stainless steel.

Pitting resistance: Due to the addition of molybdenum, the pitting resistance of 316 stainless steel plate has been significantly improved, and it can effectively resist pitting caused by corrosive media such as chloride ions. It has a wide range of applications in marine environments, chemical equipment and other fields.

Stress corrosion resistance: It has good resistance to stress corrosion cracking, and can resist the erosion of corrosive media while bearing a certain stress, thereby avoiding the occurrence of stress corrosion cracking and improving the safety and reliability of equipment.

Application field

Chemical field: used to manufacture chemical reactors, storage tanks, pipelines and other equipment, which can resist the erosion of various corrosive chemicals and ensure the safety and stability of chemical production.

Marine field: such as seawater desalination equipment, hull structure of marine ships, seawater aquaculture equipment, etc., the seawater corrosion resistance of 316 stainless steel plate enables it to be used for a long time in the marine environment.

Food and beverage industry: food processing equipment, beverage canning lines, storage containers, etc., its good corrosion resistance and hygienic performance can ensure the quality and safety of food and beverages and meet relevant hygiene standards.

Medical field: manufacturing medical equipment, hospital facilities, etc., such as surgical instruments, medical equipment shells, hospital handrails, etc., with good corrosion resistance and biocompatibility.

Building decoration field: used for exterior wall decoration, roofs, stair handrails, railings, etc. of buildings, its beautiful appearance and excellent corrosion resistance can improve the overall quality and service life of the building.

Electronic and electrical field: electronic equipment shells, radiators, wire pipes, etc., the good conductivity, thermal conductivity and corrosion resistance of 316 stainless steel plates can meet the performance requirements of electronic and electrical equipment.

FAQS

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials. .

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-45 days, and may be delayed if the demand isextremely large or special circumstances occur.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It caneffectively protect products from corrosion during ocean transportation.

Copyright © 2004-2022 Foshan Mellow Stainless Steel Co., Ltd. | All Rights Reserved 粤ICP备19129739号 Sitemap Kinlife Group Kinlife Boat Kindlemetal Stainless Steel Kitchen