Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Email: marketing_jane@mellowsteel.com

Tel/Whatsapp: +86 13138226177

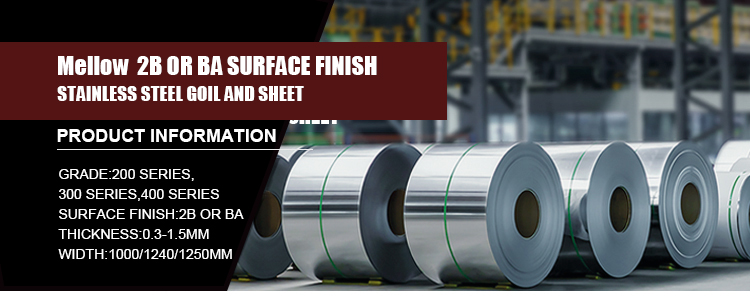

Product information

|

Brand |

Mellow |

|

Product |

430 stainless steel coil |

|

Width |

3mm-2000mm or as required |

|

Thickness |

0.1mm-3mm or as required |

|

Standard |

AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc |

|

Technique |

Hot rolled / cold rolled |

|

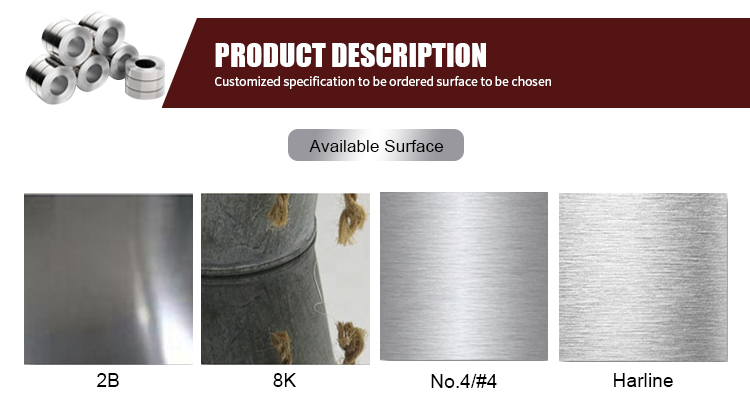

Surface |

2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc |

|

Edge |

Mill Edge, Slit Edge |

|

Packing |

Exporting wooden pallet |

|

Payment Term |

T/T, Irrevocable L/C at sight |

430 stainless steel

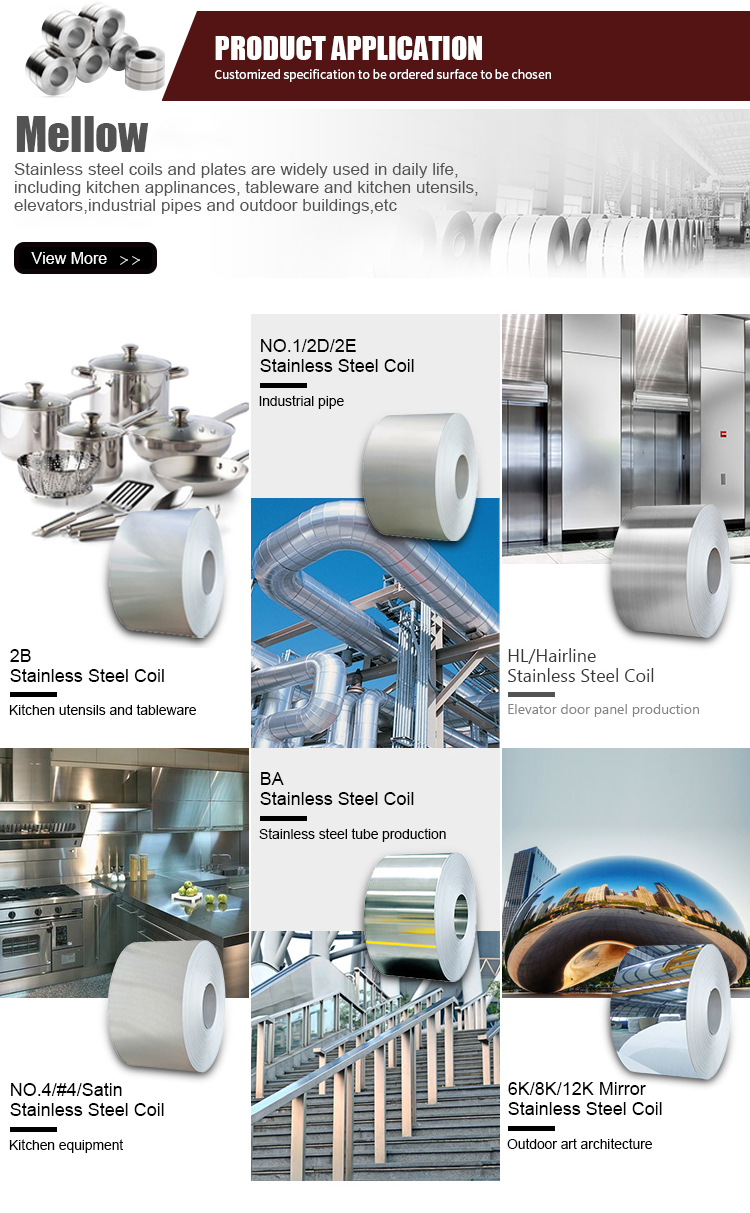

430 stainless steel plate is a common stainless steel material, which is widely used in various fields due to its excellent corrosion resistance and good forming performance. 430 stainless steel belongs to ferritic stainless steel, whose main component is chromium, and the chromium content is usually between 16% and 18%. This material is characterized by strong oxidation resistance and is suitable for environments that require high temperature oxidation resistance.

In the home appliance industry, 430 stainless steel is often used to make dishwasher inner tanks, oven inner walls and kitchen utensils, etc., because it can not only resist the erosion of food acids and alkalis, but also has good thermal conductivity. In addition, 430 stainless steel plate is also widely used in architectural decoration, such as elevator decorative panels, building exterior walls and roof decoration. These applications are not only because of its corrosion resistance, but also because of its high surface finish, which can meet the dual requirements of modern architecture for beauty and durability.However, 430 stainless steel also has its limitations. Due to its low nickel content, its welding performance is poor, so other types of stainless steel materials are usually selected in applications that require a lot of welding. In addition, compared with austenitic stainless steel, the toughness of 430 stainless steel is slightly worse, so its application is limited in some extreme environments.

430 Stainless Steel Coil Price Analysis

In recent years, with the acceleration of industrialization and the wide application of stainless steel in all walks of life, the market demand for 430 stainless steel coils has gradually increased. 430 stainless steel is widely used in kitchen utensils, home appliances, auto parts and other fields due to its good corrosion resistance and oxidation resistance. So, what is the current price trend of 430 stainless steel coils?

First, we need to understand several major factors affecting the price of 430 stainless steel coils. Raw material cost is an important factor affecting the price. 430 stainless steel is mainly composed of iron, chromium and other elements. The price fluctuation of chromium will directly affect the production cost of 430 stainless steel. In addition, the production process and technical level will also have a certain impact on the price. Advanced production technology can improve production efficiency and reduce costs, thereby forming a certain suppression on market prices.

Secondly, the market supply and demand relationship is also an important factor in determining prices. When market demand is strong, insufficient supply will lead to price increases; conversely, when market demand decreases or supply is in excess, prices may fall. In recent years, with the increasingly stringent environmental protection policies, some small production enterprises that do not meet environmental protection requirements have been forced to close, which has reduced market supply to a certain extent and pushed up prices.

Finally, the international market situation and trade policies also have an impact on the price of 430 stainless steel coils. In the international market, factors such as raw material price fluctuations, trade frictions, and exchange rate changes will have a transmission effect on domestic market prices. For example, during the Sino-US trade friction, the export of stainless steel products was affected, and domestic market prices also fluctuated accordingly.

The current price of 430 stainless steel coils shows a certain volatility, but the overall trend is stable and rising. For downstream companies, reasonable planning of procurement time and inventory management will help reduce raw material costs and improve competitiveness. At the same time, with the advancement of technology and the research and development of new materials, the stainless steel industry is also constantly innovating to meet the challenges brought about by market changes.

430 stainless steel coil processing and manufacturing process

430 stainless steel coil is a material widely used in various industries, and its processing and manufacturing process occupies an important position in the stainless steel industry. This article will introduce the processing and manufacturing process of 430 stainless steel coil in detail to help readers better understand the characteristics of this material and its application.

First of all, 430 stainless steel coil belongs to ferritic stainless steel, which has good corrosion resistance and high thermal conductivity. Its main component is chromium, and the chromium content is usually between 16%-18%, which makes 430 stainless steel coil resistant to oxidation and corrosion. In addition, 430 stainless steel coil also has good formability and mechanical properties, suitable for manufacturing home appliances, automobile exhaust systems, architectural decoration and other fields.

During the processing process, 430 stainless steel coil usually needs to undergo cold rolling and heat treatment. These two steps are key to ensuring that the stainless steel coil meets the required specifications and performance. The cold rolling process can improve the strength and surface finish of stainless steel, while heat treatment is used to eliminate the internal stress generated during the cold rolling process and further improve the physical properties of the material.

In addition to cold rolling and heat treatment, surface treatment of 430 stainless steel coil is also an important link. Common surface treatment methods include polishing, brushing and sandblasting, which can improve the appearance quality of stainless steel coils and make them more suitable for specific application scenarios. For example, in the home appliance industry, polished 430 stainless steel coils can provide better visual effects and touch.

Quality control is also a crucial part of the manufacturing process. Manufacturers usually conduct strict quality inspections on 430 stainless steel coils, including chemical composition analysis, mechanical property testing, and surface defect inspection. These inspection steps can ensure that the final product meets relevant standards and customer requirements.

In general, the processing and manufacturing process of 430 stainless steel coils involves multiple links, including cold rolling, heat treatment, surface treatment, and quality control. Through these process flows, manufacturers can produce high-quality stainless steel coils to meet the application needs of different fields. With the continuous advancement of technology, the processing and manufacturing process of 430 stainless steel coils is also constantly being optimized, providing a solid foundation for the development of the industry.

FAQS

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials. .

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-45 days, and may be delayed if the demand isextremely large or special circumstances occur.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It caneffectively protect products from corrosion during ocean transportation.

Copyright © 2004-2022 Foshan Mellow Stainless Steel Co., Ltd. | All Rights Reserved 粤ICP备19129739号 Sitemap Kinlife Group Kinlife Boat Kindlemetal Stainless Steel Kitchen