Product introduction

|

Type

|

coil

|

Thickness

|

0.3-22mm

|

Width

|

40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

|

Standard

|

ASTM,JIS, AISI, GB, DIN, EN

|

Surface

|

BA,2B,NO.1,NO.4,4K,HL,8K

|

Application

|

It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components. It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc.

|

Certification

|

ISO, SGS,BV

|

Technique

|

Cold Rolled Hot Rolled

|

Edge

|

Mill Edge Slit Edge

|

Quality

|

SGS Inspection

|

Grade(ASTM UNS) (EN)

|

410,430,201,304,304L,321,316,316L,317L,347H,309S,310S,904L,S32205,2507,254SMOS,32760,253MA,N08926,etc.

|

|

1.4301,1.4307,1.4541,1.4401,1.4404,1.4571,1.4438,1.4539,1.4547,1.4529,1.4562,1.4410,1.4878,1.4845,1.4828,1.4876,2.4858,2.4819

|

Supply Ability

|

5000 Ton/Tons per Month

|

|

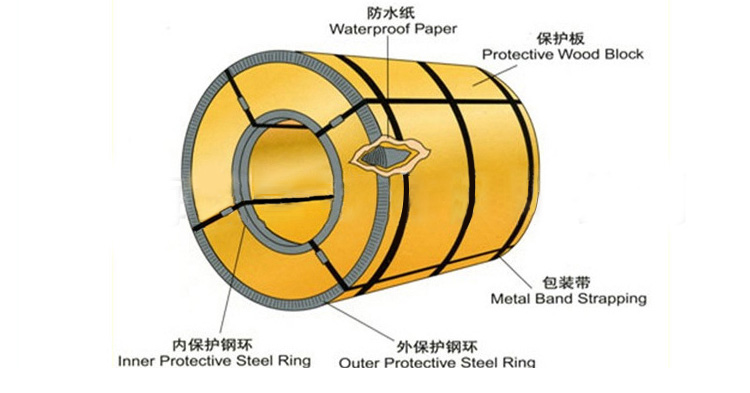

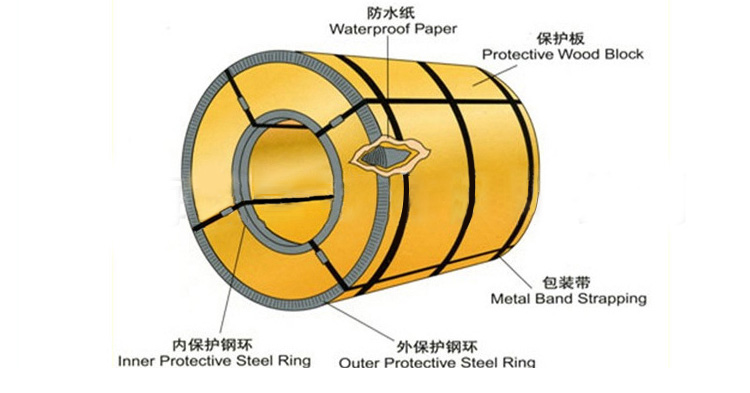

Packaging & DeliveryPackaging Detailsin bundle,plastic bags,thin film,wooden pallet,standard seaworthy export packing or as customer demands

|

|

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM

|

Chemical composition

300 series stainless steel is mainly chromium-nickel austenitic stainless steel, common such as 304 stainless steel, its chemical composition (mass fraction) is generally chromium (Cr) 18.00%-20.00%, nickel (Ni) 8.00%-10.50%; The chemical composition (mass fraction) of 316 stainless steel is mainly chromium (Cr) 16.00%-18.00%, nickel (Ni) 10.00%-14.00%, molybdenum (Mo) 2.00%-3.00%.

Performance characteristics

Corrosion resistance: Has excellent corrosion resistance, can resist the corrosion of atmosphere, fresh water, sea water and many chemical media, such as 316 stainless steel in the environment containing chloride ions and other strong corrosive media still has good corrosion resistance.

Mechanical properties: moderate strength, good toughness, low work hardening rate, easy to carry out various processing operations, such as stamping, stretching, bending, etc., it is not easy to produce cracks and other defects in the processing process, and can maintain good strength and toughness in a wide temperature range.

Magnetic: usually non-magnetic, but in special cases such as cold working may appear weak magnetic.

Application field

Chemical industry: used to manufacture a variety of chemical equipment, pipelines, reactors, etc., such as 316L stainless steel because of its good corrosion resistance and resistance to intergranular corrosion, in chemical production is widely used in contact with corrosive media parts.

Food processing industry: 304 stainless steel is a common material for food processing equipment, storage containers, transportation pipelines, etc., which meets food hygiene standards and can ensure the safety and quality of food.

Medical devices: 304 and 316 stainless steel are widely used in medical devices, such as surgical instruments, dental equipment, medical devices implanted in the human body, etc., which need to have good corrosion resistance, biocompatibility and mechanical properties.

Architectural decoration: can be used for decorative panels, curtain walls, roofs, doors and Windows of building facades, with beautiful, durable, corrosion resistance and other advantages, can maintain a good appearance for a long time.

Automotive industry: in the automotive exhaust system, engine parts, body structure parts and other aspects of the application, such as 304 stainless steel can be used to manufacture automotive exhaust pipes, radiators and so on.

Common grades and features

304 stainless steel: is a kind of universal stainless steel, with good corrosion resistance, heat resistance, low temperature strength and mechanical properties, stamping, bending and other hot processing good, no heat treatment hardening phenomenon, widely used in medical equipment, building materials, chemicals, ship parts, auto parts, food industry, household goods and other fields.

304L Stainless steel: 304 stainless steel with low carbon content, in the general state, its corrosion resistance is similar to 304 steel, but after welding or stress relief, its grain boundary corrosion resistance is excellent, suitable for welding and high requirements for grain boundary corrosion, such as chemical, coal, petroleum industry field open-air machinery, Heat resistant parts of building materials and parts with difficulty in heat treatment.

316 stainless steel: contains molybdenum element, so in the Marine and chemical industry environment of point corrosion resistance is much better than 304 stainless steel, suitable for large boiler superheater, reheater, steam pipe, petrochemical heat exchanger pipe fittings, can be used as point corrosion resistance material.

316L stainless steel: ultra-low carbon Austenitic stainless steel, has good grain boundary corrosion resistance, good corrosion resistance to organic acids, alkali, salts, widely used in acid pipelines and chemical equipment.

FAQS

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials. .

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-45 days, and may be delayed if the demand isextremely large or special circumstances occur.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It caneffectively protect products from corrosion during ocean transportation.