Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Email: marketing@mellowsteel.com

Tel/Whatsapp: +86 13827707434

200 series stainless steel introduction

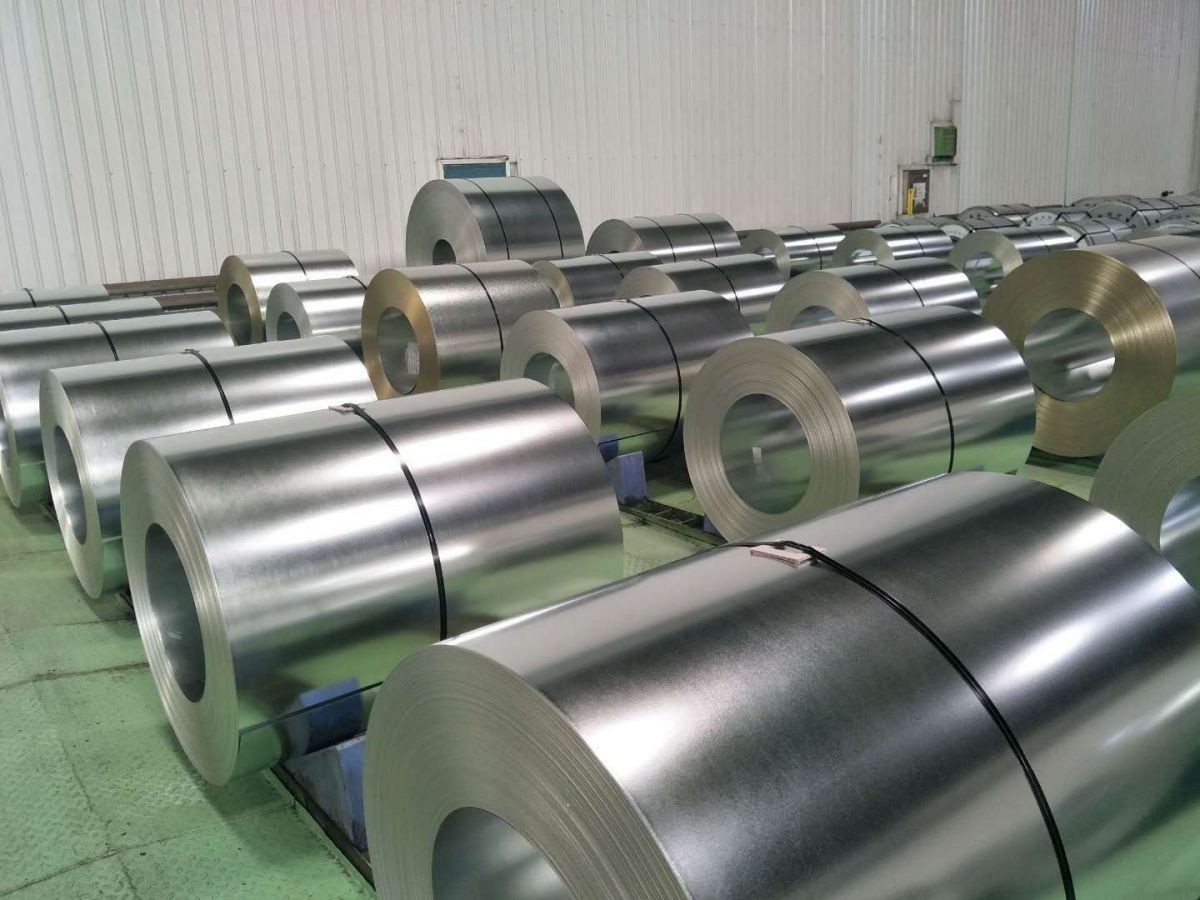

We have large stock and various series of stainless steel product, therefore we are able to offer a price of stock and quick response on delivery. Available stainless steel grades are 200 series, 300 series, 400 series, 900 series, etc. Moreover, free sample and additional services are available, like providing MTC, cutting, bending, etc. If you can't find what you need, please contact us to get our one-for-one service and a free sample.

Standard

ASTM,AISI,SUS,JIS,EN,DIN,BS,GB

Finish(Surface)

NO.1(Hot Rolled), NO.2B(Cold Rolled), Hairline, Brushed, BA, NO.3, NO.4, NO.240, NO.400, NO.8 etc.

Grade

201/202/304/309/309S/310/310S/304/304L/316/316L/316Ti/410/420/430

Standard Thickness

3mm-15mm (Hot Rolled), can be customized

Standard Thickness

0.3mm-8mm (Cold Rolled), can be customized

Standard Width

1000mm/1250mm/1500mm, can be customized

Additional Services

Welding/Punching/Cutting/Bending/Decoiling

Package Details

Standard seaworthy package(protected by waterproof paper,wrapped in iron sheet, fixed by steel bars)

The stainless steel product on the form are our stock of regular material and size, which we can send the goods within 3-5 days. If your purchase demand is out of this range, please contact us to get a customized plan, including material, size and surface customization, also sample performance testing is available.

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials. .

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-45 days, and may be delayed if the demand isextremely large or special circumstances occur.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It caneffectively protect products from corrosion during ocean transportation.

Copyright © 2004-2022 Foshan Mellow Stainless Steel Co., Ltd. | All Rights Reserved 粤ICP备19129739号 Sitemap Kinlife Group Kinlife Boat Kindlemetal Stainless Steel Kitchen