1. Basic concept of stainless steel 304

Stainless steel 304 is a universal stainless steel material, which belongs to austenitic stainless steel. Austenitic stainless steel is characterized by good corrosion resistance, toughness and machinability. The chemical composition of 304 stainless steel mainly includes about 18% chromium (Cr) and about 8% nickel (Ni), and the rest is mainly iron (Fe) and a small amount of other elements. The presence of chromium forms a dense chromium oxide protective film on the surface of stainless steel, which can effectively prevent corrosive media such as oxygen and moisture from reacting with the metal inside the stainless steel, thereby providing good corrosion resistance. Nickel helps to stabilize the austenite structure and enhance the toughness and plasticity of stainless steel.

304 stainless steel is widely used in many fields, such as food processing equipment, kitchen utensils, architectural decoration, chemical equipment, etc. In the food processing industry, its corrosion resistance ensures the safety and hygiene of food; in architectural decoration, it can be used to make handrails, doors and windows, etc., which are both beautiful and durable.

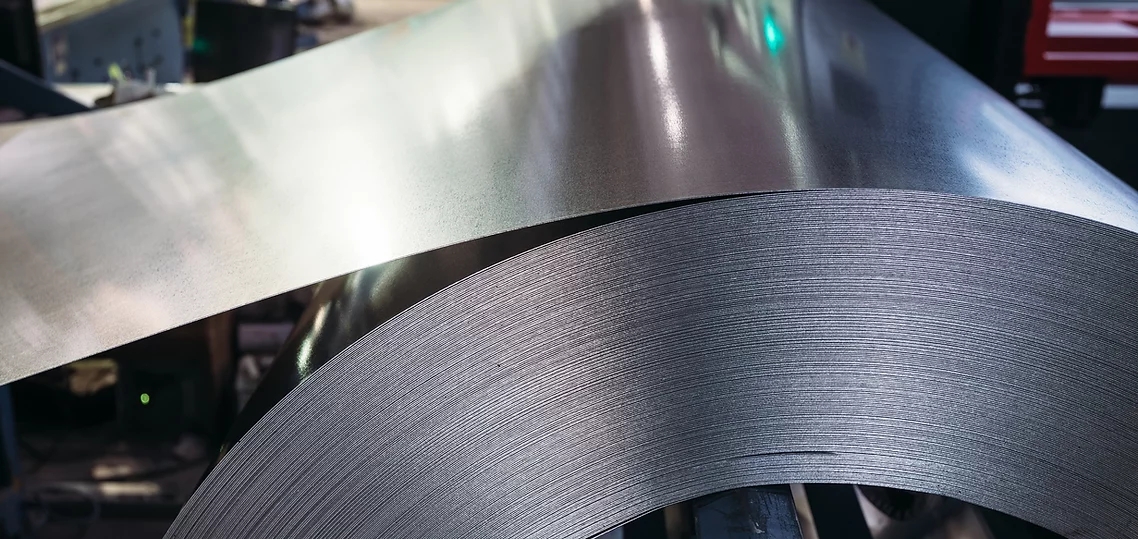

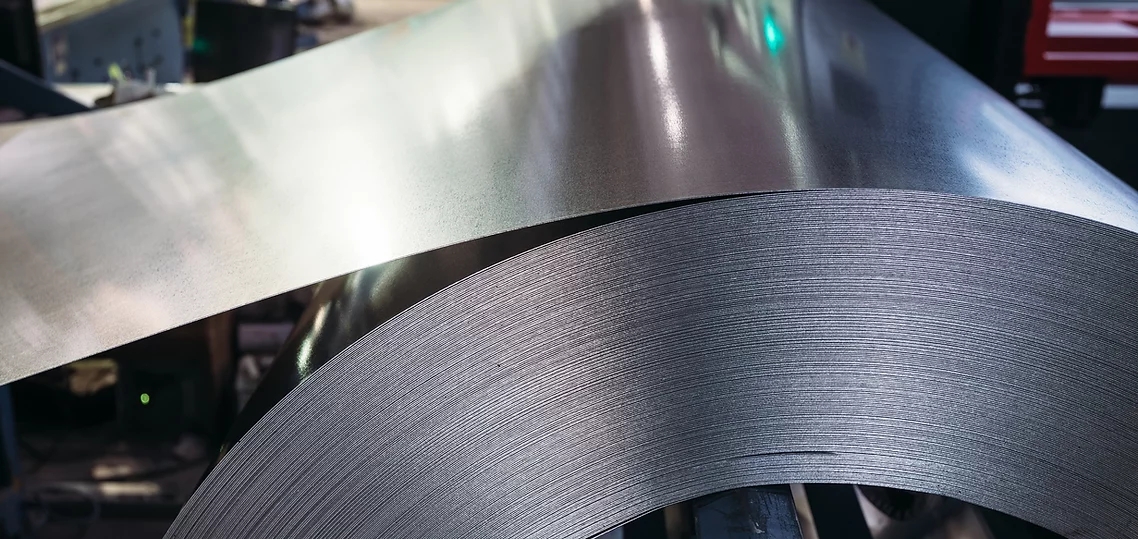

2. About "2B" surface treatment

"2B" is a common processing state of stainless steel surface. It is a surface finish obtained by processes such as heat treatment, pickling and cold rolling oil removal after cold rolling. The stainless steel after this surface treatment has a certain gloss, a relatively flat and smooth appearance, and a low surface roughness.

Compared with other surface treatment methods, stainless steel with 2B surface has better machinability. For example, when making stainless steel products in the future, the 2B surface is easier to bend, stamp and other processing operations, and can maintain a good appearance quality after processing. It is also suitable for some occasions that require a certain gloss but do not need to be as high gloss as a mirror, such as the shell of kitchen appliances, the outer surface of some industrial equipment, etc.

Stainless steel 304 2B refers to 304 stainless steel material that has undergone 2B surface treatment. This material combines the excellent performance of 304 stainless steel itself and the characteristics of 2B surface treatment, and has been widely used in many industries.

3. How is the corrosion resistance of stainless steel 304 2B?

Corrosion resistance in general corrosive environments

Stainless steel 304 2B has excellent corrosion resistance in general atmospheric environments. This is because it contains about 18% chromium, which reacts with oxygen in the air to form a dense, continuous chromium oxide (Cr₂O₃) protective film on the surface of the stainless steel. This protective film is very stable and can effectively prevent moisture, oxygen and other pollutants in the air (such as sulfur dioxide) from further eroding the metal matrix inside the stainless steel. For example, in urban environments or indoor environments, even if exposed to air for a long time, stainless steel 304 2B will not rust easily, and its appearance can remain bright and new.

In freshwater environments, stainless steel 304 2B also exhibits good corrosion resistance. This is mainly due to its stable passivation film, which can resist the erosion of dissolved oxygen in water. However, in water with a high concentration of chloride ions (Cl⁻), such as seawater or some contaminated industrial wastewater, its corrosion resistance will be affected to a certain extent. Chloride ions can penetrate the chromium oxide protective film and destroy the integrity of the passivation film, resulting in local corrosion of stainless steel, such as pitting.

Corrosion resistance in chemical media

Stainless steel 304 2B can maintain good corrosion resistance in some weakly acidic and weakly alkaline chemical media. For example, in the pH range of 4-9, its passivation film can exist relatively stably to prevent the reaction of chemical substances with the metal matrix. However, its corrosion resistance will decrease in strong acidic (such as hydrochloric acid, sulfuric acid) or strong alkaline (such as sodium hydroxide) environments. Strong acidic environments will dissolve the chromium oxide protective film, exposing the metal matrix and reacting with the acid; although strong alkaline environments will not corrode as quickly as strong acidic environments, they will also corrode stainless steel 304 2B in high temperature and high concentration alkali solutions.

For some chemical media containing oxidizing substances, such as nitric acid, stainless steel 304 2B has good corrosion resistance. Nitric acid can strengthen the passivation film on the surface of stainless steel, further improving its corrosion resistance. However, if the medium also contains substances such as chloride ions that destroy the passivation film, its corrosion resistance will also be affected in a complex manner.

Corrosion resistance in high temperature environment

In the medium temperature range (generally below 500℃), the corrosion resistance of stainless steel 304 2B can basically be maintained. However, as the temperature increases, its oxidation rate will accelerate, and the chromium oxide protective film on the surface may change. In a high temperature and oxygen environment, stainless steel may oxidize and form a thicker oxide layer. If the oxide layer can remain continuous and dense, it can still play a certain protective role; but if the oxide layer peels off or cracks, it will cause the corrosion resistance of stainless steel to decrease.

In an environment with high temperature and corrosive elements such as sulfur, such as the sulfur-containing flue gas environment generated in some industrial combustion processes, stainless steel 304 2B may be corroded by sulfides. Sulfides will react with the chromium oxide protective film on the surface of stainless steel, destroying the integrity of the protective film, and then causing the stainless steel to corrode.

4. How to judge the quality of stainless steel 304 2B?

Appearance inspection

Surface flatness: The surface of good quality stainless steel 304 2B should be flat and smooth. Touch the surface with your hand, and there should be no obvious unevenness or waves. Place the plate in a well-lit place and observe whether the reflected light is uniform. If the surface is undulating, the light reflection will be distorted. This is because during the production process, if the rolling process is not up to standard, the surface will be uneven.

Color uniformity: Its color should be uniform and consistent. High-quality 304 2B stainless steel usually presents a bright silver color, and there is no color spot, color difference or yellowing on the entire surface. If the surface color of stainless steel is uneven, it may be contaminated during the processing process, or the composition of the material itself is uneven. For example, stainless steel with more impurities may have local changes in surface color.

Scratch and defect inspection: Carefully check the surface for scratches, abrasions or pits. Minor scratches may affect the appearance, but deeper scratches may damage the passivation film on the surface of stainless steel and reduce its corrosion resistance. By irradiating with oblique side light, the subtle scratches and defects on the surface can be observed more clearly. These scratches may be caused during transportation, processing or storage.

Chemical composition analysis

Chromium (Cr) and nickel (Ni) content: The main alloying elements of 304 stainless steel are chromium and nickel. The chromium content is about 18% and the nickel content is about 8%. Accurate chemical composition analysis requires professional equipment, such as a spectrometer. By detecting the chromium and nickel content, it can be determined whether the stainless steel meets the 304 standard. If the chromium and nickel content is insufficient, the corrosion resistance and toughness of the stainless steel will decrease. For example, low chromium content will lead to incomplete formation of the surface passivation film, making the stainless steel easy to rust.

Impurity element inspection: Check whether there are too many harmful impurity elements, such as sulfur (S) and phosphorus (P). Sulfur and phosphorus will reduce the toughness and corrosion resistance of stainless steel. In high-quality 304 2B stainless steel, the sulfur and phosphorus content should be controlled at a very low level. Generally speaking, the sulfur content should not exceed 0.03% and the phosphorus content should not exceed 0.045%. If the impurity element content is too high, the stainless steel may crack or its corrosion resistance may deteriorate during processing or use.

Physical property test

Hardness test: A hardness tester can be used to test the hardness of stainless steel 304 2B. Appropriate hardness indicates that the material has good wear resistance and deformation resistance during processing and use. For 304 2B stainless steel, its hardness is generally around Brinell hardness (HB) 187. If the hardness is too high, it may affect its processing performance, such as bending, stamping and other operations will become difficult; if the hardness is too low, it may be prone to scratches and deformation during use.

Density detection: The theoretical density of 304 stainless steel is about 7.93g/cm³. By measuring the density, it can be preliminarily determined whether the material meets the standard. If the density deviation is large, it may indicate that there are defects such as voids and inclusions inside the material, or the composition does not meet the requirements. However, density detection requires precise measurement tools and methods, such as using the drainage method combined with a high-precision balance to measure volume and mass.

Corrosion resistance test

Salt spray test: This is a commonly used test method to simulate a harsh corrosion environment. Place the stainless steel 304 2B sample in a salt spray test chamber and conduct a spray test according to certain standards (such as neutral salt spray test, sodium chloride solution concentration of 5%, temperature of about 35℃). After a certain period of time (such as 24 hours, 48 hours or 72 hours), observe whether there are rust spots, corrosion pits and other phenomena on the surface of the sample. High-quality 304 2B stainless steel should not show obvious signs of corrosion in a shorter salt spray test.

Immersion test: According to the possible use environment of stainless steel, select the corresponding chemical solution for immersion test. For example, for stainless steel used in the food processing industry, it can be immersed in a solution containing a certain concentration of acetic acid, citric acid or sodium chloride to simulate the acidic and saline environment in food. After soaking for a period of time (such as one week or one month), check the weight change, surface state, etc. of the sample. If the weight loss is small and there is no obvious corrosion on the surface, it means that its corrosion resistance is good.

Process quality inspection

Edge processing quality: If it is a stainless steel plate, check whether the edge is neat and smooth. The edges of high-quality 304 2B stainless steel sheets should be finely cut or processed, without burrs, cracks and other defects. The edge quality not only affects the appearance, but also the subsequent processing and safety of use. For example, the edges with burrs may scratch the operator during installation or cause poor sealing during use.

Dimensional accuracy: Check whether the dimensions of the stainless steel meet the specified standards. For stainless steel materials of different shapes such as pipes and plates, the length, width, thickness, outer diameter and other dimensions should be within the specified tolerance range. If the dimensional accuracy is not enough, it may cause problems during assembly, such as failure to connect tightly or gaps after installation.