Why specify PVD coated colored stainless steel?

Durability

1.Scratch resistant making it highly durable for high traffic and heavy- wear areas

2.The PVD coating creates a tough finish which is approximately ten times harder than stainless steel itself

3.Twelve year guarantee.

Eco-friendly

1.Stainless steel material is 60% recycled and 100% recyclable.

Cost – effective

1.Allows less expensive standard ranges to be specified with colour- matched workshop-fabricated items acting as feature pieces or as essential supplements to a cheaper range

2.Can recolour existing fittings, components and lighting enabling re-utilisation of fixtures for new re-fits.

Hygienic

1.Antimicrobial finish suited to food preparation, medical and laboratory environments and public areas.

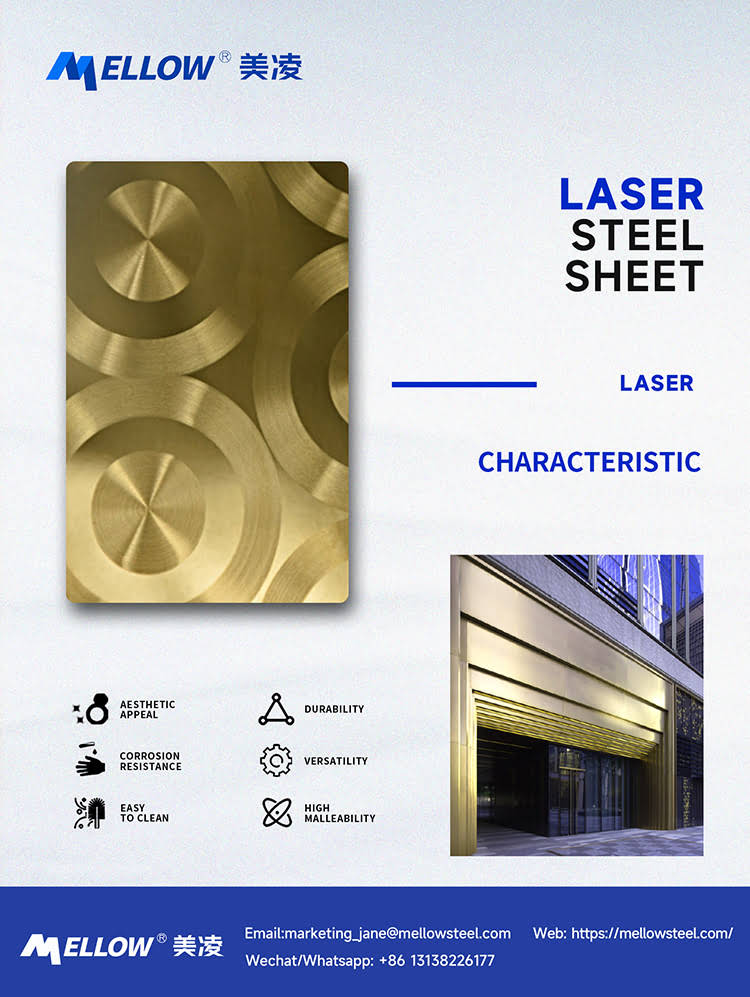

Finishes Also available:

1.Embossed finishes, coloured and uncoloured.

2.Anti-fingerprint finish.

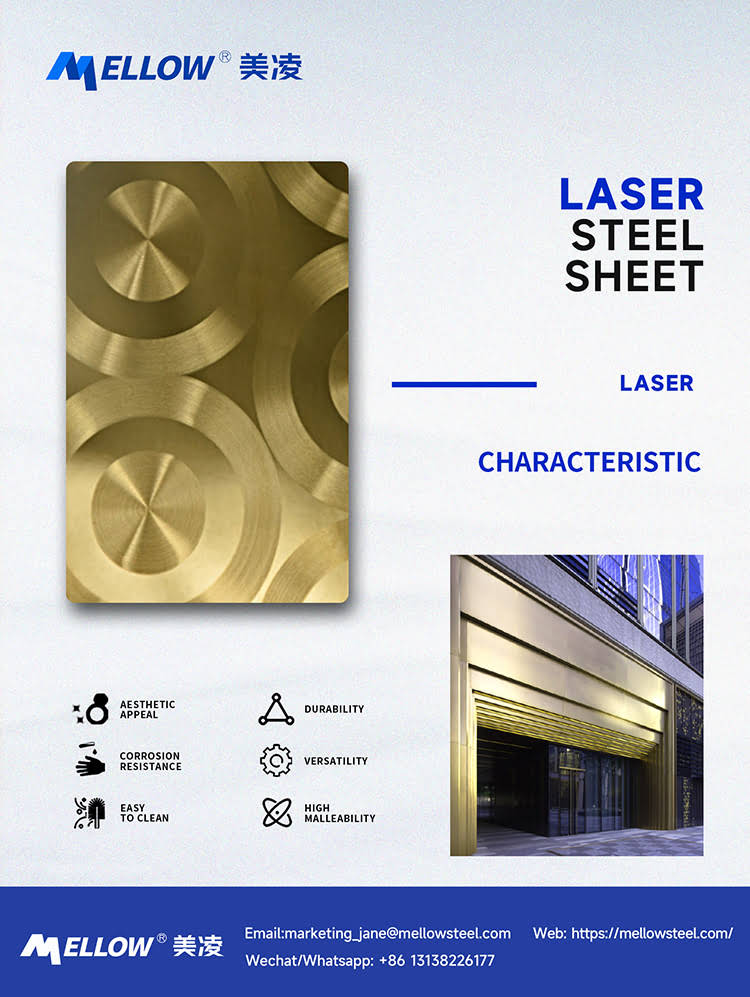

A spectrum of colour options

1.Can be colour-matched to other finishes and materials

2.Can be specified in a wide spectrum of colours

3.Mimics more expensive materials such as bronze, brass and gold providing a cost-effective, easy-maintenance alternative

4.Can be completely colourless for a natural stainless steel appearance

Key properties

1.Standard PVD coating is 0.35 microns thick

2.Flush finish where two PVD coatings meet

3.Creates a metal-against-metal lubricant

4.Can be re-coated once coated